How can the mechanical structure of a pedestrian access gate be optimized to reduce wear and tear over time?

Release Time : 2025-10-15

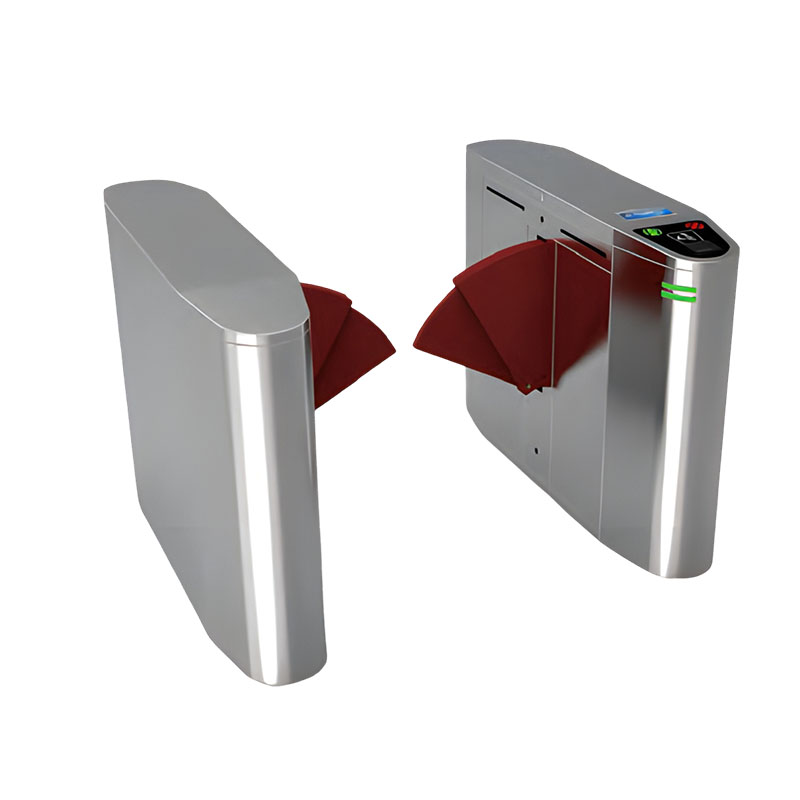

As a core device for access control, the stability of a pedestrian access gate's mechanical structure directly impacts its service life and operational efficiency. Over long-term use, wear and tear of mechanical components can lead to jamming, unusual noises, and even malfunctions. Therefore, systematic optimization is required across four dimensions: material selection, structural design, lubrication and maintenance, and intelligent monitoring.

Materials are the foundation of mechanical structures. Traditional pedestrian access gates are often made of ordinary steel, but prolonged exposure to humidity or large temperature fluctuations can easily lead to rust, causing transmission components to jam. Optimization efforts are focused on using high-strength stainless steel or aluminum alloys, which are not only corrosion-resistant but also withstand the stresses of frequent opening and closing. For example, aluminum alloy mechanisms offer improved fatigue resistance compared to traditional materials while maintaining a lightweight design, significantly extending the service life of key components.

Structural design must balance functionality and durability. Traditional swing gates have direct contact between the drive shaft and bearings, which can easily cause wear due to friction over time. An optimization solution involves adopting a modular design, independently encapsulating the transmission system to reduce the intrusion of dust and foreign matter. Furthermore, buffer springs are added at the connection between the swing arm and the base to absorb impact and prevent deformation caused by hard collisions. For wing gates, the flap's deployment angle and speed profile can be optimized to achieve a smoother opening and closing process and reduce wear on the rails.

Lubrication is a key step in reducing wear. Traditional lubrication methods rely on periodic manual application of grease, but this can be ineffective due to uneven application and environmental influences. An optimization approach involves using self-lubricating bearings or oil-retaining cages. These components are injected with a solid lubricant during manufacturing, which continuously releases lubricant during operation, reducing maintenance frequency. Furthermore, high-molecular-weight composite grease is used in gear meshing. Its high-temperature and water-wash resistance ensures long-term lubrication, making it particularly suitable for outdoor use.

Intelligent monitoring technology supports preventive maintenance. Traditional maintenance relies on regular inspections, but it is difficult to accurately locate early signs of wear. An optimization solution involves embedding vibration and temperature sensors in key locations, such as the movement and drive shaft, to collect and analyze component operating conditions through real-time data collection. For example, if the vibration frequency exceeds a threshold, the system can provide an early warning of gear wear; if the temperature rises abnormally, it can indicate insufficient bearing lubrication. Combined with AI algorithms, this can also predict the remaining life of components, guiding maintenance personnel in precise replacement procedures and avoiding unnecessary repairs or unexpected failures.

Optimizing the transmission system requires a balance between efficiency and reliability. Traditional belt drives are prone to slippage due to aging and loosening, while chain drives are subject to noise and wear. An optimization approach is to use a combination of a synchronous belt and a tensioner. The high-precision transmission of the synchronous belt ensures synchronization of the swing arms, while the tensioner automatically adjusts tension, extending the belt's lifespan. For high-traffic applications, a servo motor direct drive system can be used. Its continuously variable speed capability adapts to varying traffic speeds while reducing wear on intermediate transmission links.

Environmentally adaptable designs can reduce wear caused by external factors. In coastal areas or high-humidity regions, traditional metal components are susceptible to corrosion and rust caused by salt spray. An optimization solution involves applying a nano-hydrophobic coating to the surface of the mechanism, forming a protective film that isolates moisture and salt. For cold northern regions, low-temperature grease is required to prevent the lubricant from solidifying due to low temperatures. Furthermore, in dusty environments, filters can be added to the air inlet to reduce dust intrusion into the mechanism.

Optimizing the mechanical structure of pedestrian access gates requires a coordinated approach encompassing multiple dimensions: materials, design, lubrication, monitoring, transmission, and environmental adaptability. By selecting corrosion-resistant materials, modular structural design, self-lubricating technology, intelligent monitoring systems and improved environmental adaptability, wear during long-term use can be significantly reduced, the stability and life of equipment operation can be improved, and more reliable protection can be provided for entrance and exit management.